Hierarchical Intelligent Control of Production Systems: A Fuzzy Logic Perspective

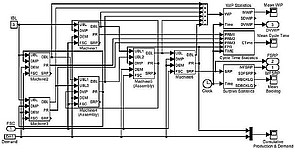

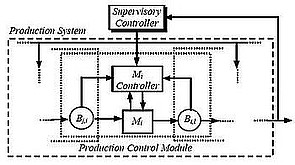

In this research project a supervisory control scheme is developed for scheduling (single/multiple-part-type, re-entrant) production networks. The overall production control system is viewed as a two-level surplus-based system with the overall control objective to keep the WIP and cycle time as low as possible maintaining at the same time quality of service by keeping backlog into acceptable levels. A supervisory controller is used to tune a set of lower level distributed fuzzy control modules. The production rate in each production stage is controlled to satisfy demand, avoid overloading and eliminate machine starvation or blocking. The use of the lower level distributed fuzzy control modules without supervision has given very good results compared to other production control approaches in reducing WIP and Cycle Time while satisfying demand. One of its major advantages is that due to its modularity and distributivity (one controller at each production module), it is easily implemented in production systems of almost any geometry and magnitude. With the use of a supervisory fuzzy controller the system's performance is considerably improved for a number of performance measures. Extensive simulation results show that the supervisory controller when compared with the single level distributed fuzzy controllers reduces WIP and Cycle-Time while keeping backlog in acceptable levels.

The project was funded by the Greek Secretariat for Research and Technology through the EU Bilateral Agreements Program Greece – Slovenia 2000-2002. The institutions tha participated in the project are the Technical University of Crete, Greece) and the University of Maribor, Slovenia.